A Brief Outlook On Industrial Cooker Mixer And Filling Machines

Industrial cooker mixer can perform a wide range of specialty mixing tasks thanks to their many accessories. For every industrial kitchen, they are a necessary piece of equipment. A bowl, a bowl lift wheel, a bowl guard, front and rear covers, mixing accessories, and onboard controls are features that almost all commercial kitchen mixers include.

However, there are a few various mixer designs to pick from, so before window shopping, it helps to know how you’re going to utilize it. We’ve covered how to purchase your first Industrial cooker mixer in this in-depth article, along with a discussion of the many mixer types, motor systems, and accessories.

This guide will assist you in focusing your search for the ideal mixer because some mixer setups are better suite for particular businesses and types of food.

What can you do with a commercial kitchen mixer?

There are many uses for a commercial mixer, from making large quantities of pizza dough to operating a full-fledged bakery.

The main mixer types and their intend applications are list below:

Planetary mixers:

The action of the mixer, which revolves around the bowl like a planet around the Sun, gave rise to the name. Making freshly whipped cream, mashed potatoes, and other foods with a lot of moisture is no problem with these commercial mixers. Chefs may use planetary mixers in a variety of ways since they include at least four agitator attachments.

Spiral blenders:

Spiral mixers, so named because of the design of their agitator attachment, frequently feature quicker motors than planetary mixers. They are sometimes referred to as “dough mixers” because of how well they work when mixing thick dough in large quantities. Spiral mixers are frequently used by large-scale bakeries and pizzerias to get through a busy service. Some spiral mixers, particularly those with hydraulic bowl lifts, are capable of handling up to 600 pounds of dough. To raise bulky bowls and prepare the dough, special lifters are used.

Mixers with vertical cutters:

A vertical mixer is made with a cover mixing bowl and a strong motor for quick mixing without a mess. They work well for mixing bread, meat, and veggies. They are also use in some kitchens to combine silky mousses.

Every commercial mixer is made to withstand severe usage, yet some do particular jobs better than others. Look closely at the mixer’s specifications online before purchasing to see what its limitations are.

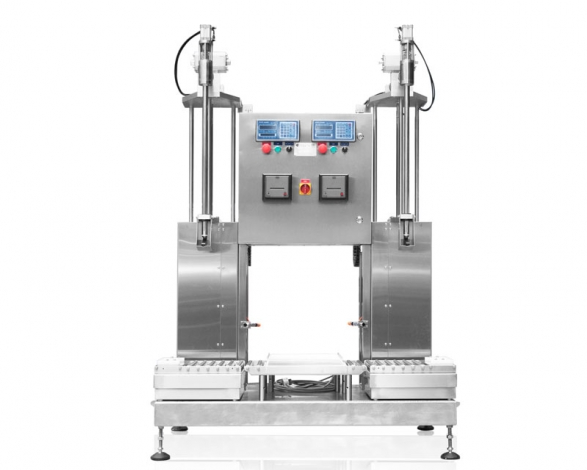

Pail filling machine: What is it and how does it work?

Have you ever considered how the contents of bottles, tubes, cans, and containers of all types and sizes are place within them? Well, the magic is over. Industries employ a Pail filling machine to fill all different types of containers.

Examples of businesses that employ this kind of equipment include:

- Drugs and Pharmaceuticals

- Food and Drink

- Related Products for Paint

- Occupational Chemicals

- Licensed Packaging

- Distilleries and many others

Are they all used for the same thing?

The many filling, capping, and other comparable machine types are as varied as the goods and businesses that need them to function! The machine’s design is specifically built to handle particular jobs and deliver particular goods. These machines may also be divide into two primary categories: automated production filling machines and semi-automatic production filling machines.

The large range of these sorts of machines available in the market today properly satisfies every demand for a filling machine in any business.

Several of the most typical machines are as follows:

Added filler:

In many different sectors, this equipment is most frequently use to fill tiny bottles. The overflow filling machine is perfect for sectors that need to fill a lot of containers because of how easy it is to put up and take down. These machines, which are built with foam control technology, are frequently utilize in applications demanding fill-to-glass requirements.

Weigh filler net:

The net weight filling machine is a scale-based machine that can handle nearly any form of weight-based filling activity. It is most frequently employee in sectors where items are fill by weight. These machines can handle tasks that need the exact filling of small weights, large weights, and everything in between. They are typically use to fill totes or pails.

Gravity Filler for Time:

Companies that produce very thin liquids with little to no particles, whose physical characteristics do not alter with changes in temperature or the atmosphere, are most suited to employ this sort of equipment. Time gravity filling machines are ideal for use in the chemical industry since they can handle these kinds of liquids with ease.

These are only a handful of the many different types of filling machines that are offer to companies throughout the world. These devices are made and engineere to ensure that your product is sold as quickly and effectively as feasible.